In today’s fast-paced cold-chain environment, unplanned equipment failures can bring operations to a standstill, jeopardising product integrity, inflating maintenance costs and eroding customer trust. Real-time telematics offers the visibility needed to catch anomalies early and transition from reactive repairs to predictive maintenance.

Why Predictive Maintenance Matters

-

Reduced Unplanned Downtime

By continuously monitoring metrics such as temperature excursions and vibration levels, fleets can schedule interventions before minor issues escalate into full breakdowns.

-

Optimised Maintenance Costs

Maintenance based on actual equipment condition avoids both premature part replacements and emergency call-outs, maximising return on investment

-

Regulatory Compliance

Automated logging of temperature and runtime data supports audits under regulations like the FSMA (Food Safety Modernisation Act) and emerging F-Gas rules.

Key Telematics Metrics to Monitor

|

Metric

|

Insight Provided

|

|

Temperature Excursions

|

Detects deviations beyond set thresholds—prevents spoilage

|

|

Runtime Hours

|

Informs optimal service intervals

|

|

Vibration Analysis

|

Flags mechanical wear before catastrophic failure

|

|

Battery Voltage

|

Ensures uninterrupted device connectivity

|

ORBCOMM Solutions for Predictive Maintenance

- 3G→4G LTE Network Gateway (MPN3801)

Maintains continuous connectivity by auto-switching legacy 3G units to 4G LTE, eliminating data gaps.

|

|

- GT-Series Gateways (MPN3800)

Perform edge-computing tasks, filtering out transient events (e.g. brief door openings) to reduce false alarms and data costs.

|

|

- RX3 Temperature Recorder (MPN3661)

Captures high-resolution temperature readings at configurable intervals, enabling granular trend analysis.

|

|

Case Study: C.R. England’s First-Year Results

ORBCOMM’s end-to-end cold-chain telematics solution was deployed across C.R. England’s 6,000+ refrigerated trailers and 1,500 intermodal reefer containers. In the first 12 months, they achieved:

- 53 % reduction in trailers idle over 30 days

- 44 % decrease in temperature-related claims, saving “hundreds of thousands of dollars”

These gains were driven by automated alerts on mechanical and decision-error conditions, plus seamless integration of telematics data into their dispatch and maintenance systems.

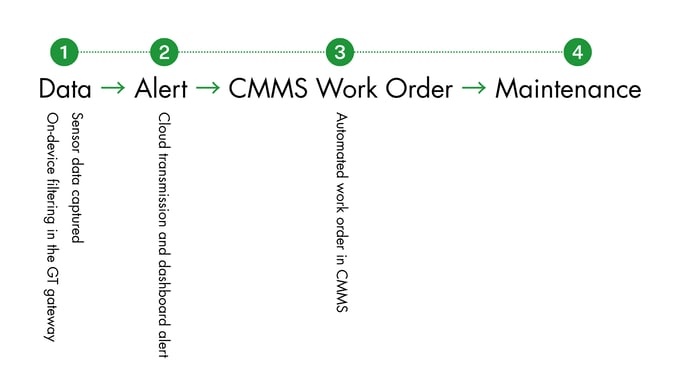

Building Your Predictive Maintenance Workflow

- Define Alert Thresholds

Work with technicians to set actionable limits (e.g. >5 °C excursion for more than 10 minutes).

- Deploy Edge-Filtering

Configure GT-Series devices to suppress false positives and focus on genuine faults.

- Integrate with CMMS

Route telematics alerts directly into your maintenance-management software to auto-generate work orders.

- Review Trends Quarterly

Analyse historical data to uncover repetitive failures and recalibrate thresholds as fleets and routes evolve.

Best Practice Tips

- Pilot on High-Value Assets before scaling fleet-wide.

- Train Your Team on interpreting telematics alerts versus real-world symptoms.

- Use Dashboards for live oversight of critical KPIs, temperature, runtime, and vibration.

- Keep Firmware Updated to leverage new analytics features and maintain security.

Ready to transform your maintenance regime?

Speak with your Myriad Parts account manager about the Orbcomm telematics solution that best fits your fleet.

Resources:

- C.R. England case study PDF: “State-of-the-art trailer tracking helps refrigerated carrier keep its cool” orbcomm.com